An efficient Farm Dairy Effluent (FDE) system will help you improve your pasture, cut fertiliser costs and make use of valuable resources.

But how do you know which one is best suited for your farm?

In this article, we’re going explore the different types of effluent systems which will help you make a decision on which one is best for your unique farm.

First, let me list the names of the 10 effluent systems we will be discussing:

- Travelling irrigator

- Low rate sprinkler with passive separation

- Low rate sprinkler with mechanical separation

- Multiple line low rate sprinkler with passive separation

- Multiple line low rate sprinkler with mechanical separation

- Pivot through mainline with passive separation

- Pivot through mainline with mechanical separation

- Pivot with under slung sprinklers

- Muck spreader

- Contract spreader

If you have high rainfall area, high water table, a sensitive catchment, poorly drained soils or soils with artificial drainage, or if you irrigate on sloping land then you should consider a low rate application system.

A sprinkler system is lower risk. You will also need extra effluent storage as you will not be able to apply effluents when your soils are wet.

If you have a large herd of over 500 cows, an intensive feeding system or a standoff or feed pad in regular use, then you should include a solid separation component to your system to deal with extra nutrients and solid before they reach storage. You also need to check if you have a large enough area for applying your effluent.

If you don’t have any of the risk factors mentioned above, you can use any type of applicator! Just make sure you have enough storage to make it through the wet times, and keep a close watch on your application rate.

Storage:

If you have sufficient storage for your effluent, you can keep it in storage and use it only when your soil conditions are right.

Your storage options can either be on ground, or in ponds and tanks that are above ground. Your storage facility has to hold your effluent without leaking so they’re usually lined with synthetic products or clay.

Using an agitator or stirrer that will continuously keep mixing your effluent is a good way to keep solids in suspension. This reduces odour and the need to keep desludging, thereby making your life easier!

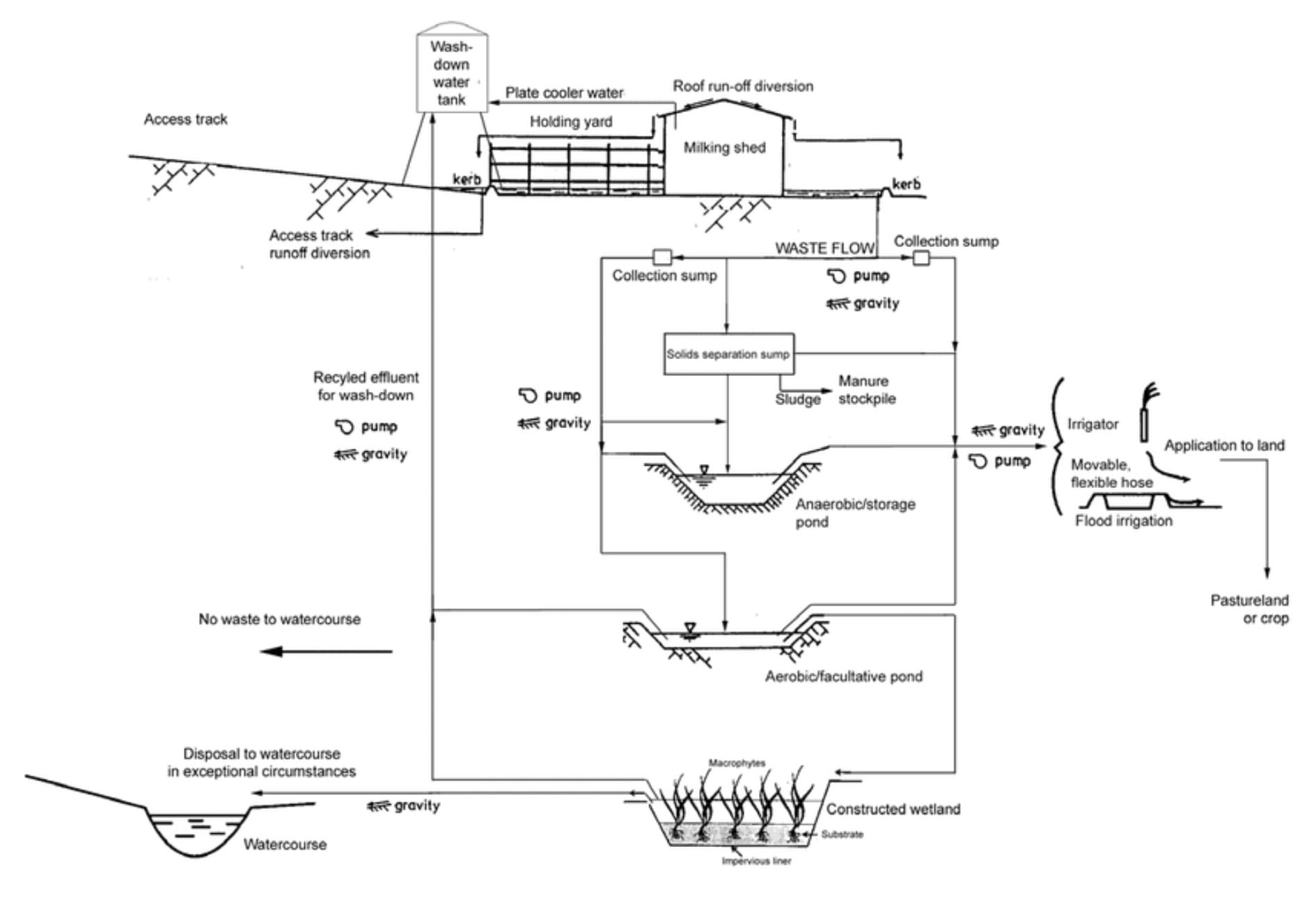

This image will help you understand the waste management options available for a typical dairy farm

So now let’s go on to discuss the 10 effluent systems in detail!

Travelling Irrigator:

I’m sure you are familiar with this traditional system that uses a storm water diversion.

Effluent flows from the yard to the storage either by free flowing, or through a pump. It is then irrigated to the land using a travelling irrigator.

You can use this system when:

- Your farm has no particular landscape, climate or soil risk factors

- Freely drained soil

- Flat ground to gentle sloping

- Moderate labour input

- Low – moderate capital investment

This is ideal for regular shaped paddocks. If you’re using a travelling irrigator on heavy soil, it must operate on fast speed to avoid over application.

Low Rate Sprinkler with Passive Separation:

This also uses a storm water diversion. First, solids are removed in a passive separator and then, the liquid is pumped to a storage system and irrigated to land via a small number of low rate applicators.

You can use this system when:

- Your farm has high risk soils, high rainfall and sensitive catchments

- All types of soil

- Different kinds of slopes

- Higher labour

- Moderate to high capital investment

This system is ideal for small and irregular paddocks.

Low Rate Sprinkler with Mechanical Separation:

This system too has a storm water diversion at the yard.

The effluent flows through a stone trap to a mechanical separator that removes solids. The liquid is pumped to storage and irrigated to the land via low rate applicators.

The only difference here is the mechanical separator as compared to the passive separator in the previous system.

Using a mechanical separator requires more labour to run the mechanical device. Using a passive separator does not require that much labour.

Multiple Line Low Rate Sprinkler with Passive Separation:

In this system, effluent flows via gravity to a passive separator that removes solids.

This liquid is then irrigated to land via irrigation lines that run simultaneously. Each line has low rate applicators that distribute large volumes of effluent quickly, at a low application depth.

You can use this system when:

- You have high rainfall with fewer number of irrigation days available

- Your farm has high risk soils

- All kinds of slopes

- Moderate labour

- Moderate to high capital investment

Multiple Line Low Rate Sprinkler with Mechanical Separation:

The only difference here is that solids are removed via a mechanical separator, and not a passive separator.

One thing to remember is that this system needs a larger pump size.

Pivot through Mainline with Passive Separation:

You can use this only when you already have pivots in place for water irrigation.

In this system, effluent goes from the dairy to a passive separator. The liquid is then pumped to storage and applied to paddocks through the pivot mainline.

You can use this system when:

- You already have irrigation pivots in place

- Suitable for all soils

- Flat slopes

- Lower labour

- Moderate to high capital investment

Pivot through Mainline with Mechanical Separation:

Here, the effluent flows to a mechanical separator, instead of a manual separator. Using a passive separator slightly reduces the labour involved.

Pivot with Under Slung Sprinklers:

Again, this system works only when you already have pivots in place for water irrigation.

The effluent is fed from the dairy through a stone trap. The liquid is pumped to the storage and applied to paddocks through under slug sprinklers.

Some effluent systems have effluent guns that are attached to the end of pivots. These cause low spread of nutrients and also increase the risk of over application. Not a good choice for your farm!

Muck Spreader:

Here, effluent is stirred and sucked from storage into a muck spreader trunk.

This is then sprayed on to the land.

If your farm has wet or heavy soils, avoid using this system. Heavy machinery will end up damaging your precious pasture and soils.

You can use this system when:

- Your farm is small and you have lower numbers of cows, or if you’re applying effluent to remote areas

- Suitable for all types of soils

- Flat to sloping lands

- When labour is moderate to high

- Capital investment is low

Contract Spreader:

In this system, effluent systems include a storm water diversion.

It then flows through a stone trap to a storage facility. If there’s no gravity for the effluent to flow, then you can use a pump station.

Contract spreaders remove the effluent from storage and apply it on to the land using their own equipment.

You can use this system when:

- You don’t have the time to look after effluent systems every day

- Suitable for all soil types

- Your farm has flat to sloping ground

- Your labour input is low

- Your capital investment is low

But remember that if you’re opting for this system, you and your farm will be entirely reliant on the contractor you choose to manage your effluent system.

Every single farm is unique. And you need to choose an effluent system that’s just right for you.

Installing a reliable effluent system is probably one of the most important decisions you will make for your farm

Two other important factors to consider before choosing your effluent system are:

Unique farm layout review: A review of the distance from your cowshed to storage pond, closeness to waterways and required head of irrigators etc.

Irrigation method: Sometimes it is good to start with the end in mind. Think about what irrigation method suits you, and then work backwards from there!

Some irrigators can take more solids than others. This will help you determine the level of separation required. You also take into consideration your soil type and irrigation area when you choose an irrigation method, don’t you? This will help you figure out what depth the effluent can be spread.

In short, there are a whole bunch of things to think about when choosing your effluent system. And it’s really exciting – especially when you have so much to gain with a good effluent system that will last for many milking years!

Happy Farming!

- The Dedicated Team of Pasture.io, 2020-09-01