| When you have a good effluent system, it improves your pasture and reduces your spending on fertilisers.

Good effluent management is having a well-designed effluent system, and having staff who make sure that the effluent collected is properly applied to the pasture in the right quantity at the right time.

The average dairy cow produces $25 worth of nutrients in a year as farm dairy effluent (FDE). For a herd that has about 400 cows, this sums up to $10,000 of nutrients per year. Using this effectively as a resource, and not dumping it as waste, has a whole lot of benefits.

Good effluent management will help you:

- Save money spent on fertilisers

- Improve your soil

- Prevent health issues in your animals

When you want to make a good effluent irrigation decision, you have to first understand your soil water deficit. So what is soil water deficit?

Soil water deficit is the amount of water (effluent) that can be applied to the soil before it reaches field capacity.

Field capacity is the amount of water that the soil can hold after the excess water has been drained.

If you keep applying effluent even after the soil reaches field capacity, it leads to ponding, runoff and leaching.

Effluent can be of three types, based on the DM content:

Liquids (0-5%) Mostly made up of animal excreta, teat washings and wash down water. It can be sprayed as a liquid using irrigation equipment. Since it is high in water content, it is used for effluent management blocks that are close to the milking shed.

Slurries (5-15%) Slurries are usually made up of excreta plus additives like water and feeds. It has a semi-liquid form and can be sprayed from a slurry tanker. Like liquids, these can’t be applied through irrigation pipes due to the high DM content.

Solids (>15%) This refers to organic manure that could either be solid or semi-solid. They’re usually stacked in a heap and are applied using muck spreaders.

What is in FDE?

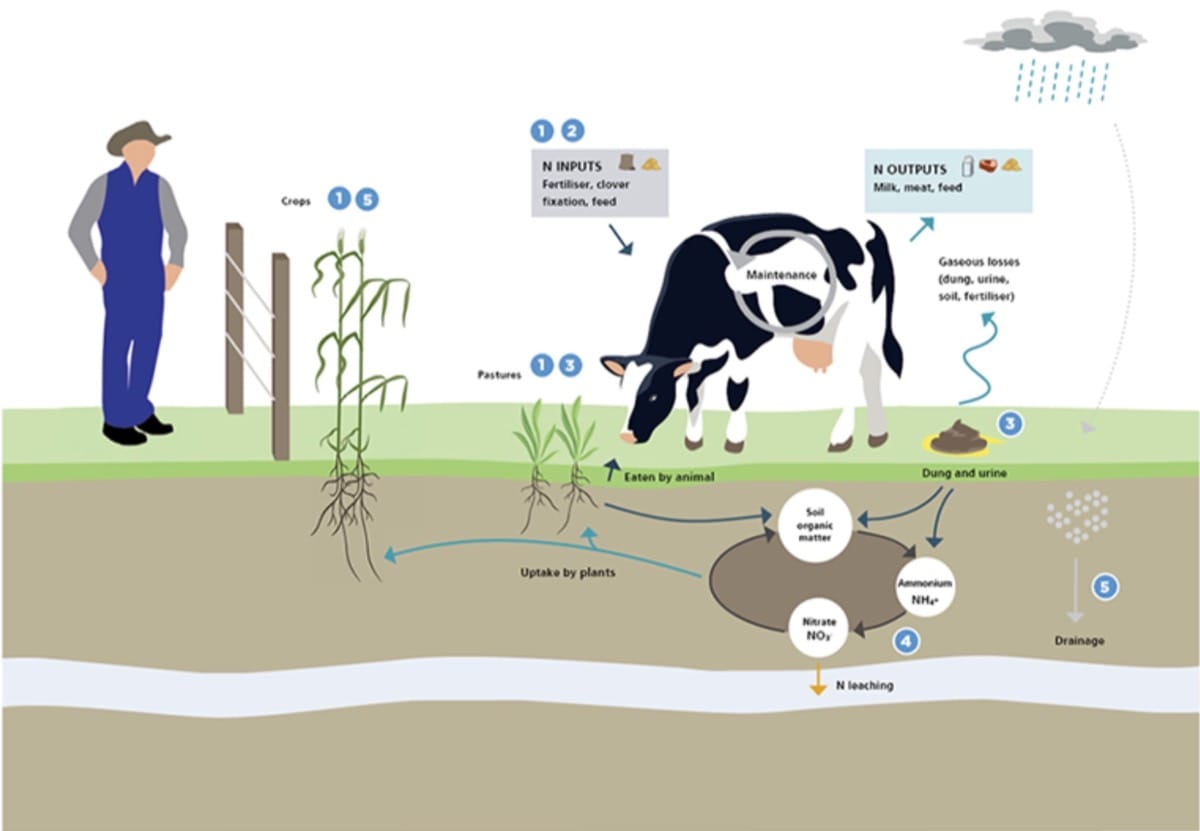

The major nutrients in FDE are nitrogen (N), phosphorus (P), potassium (K) and sulphur (S). FDE also contains organic matter in the form of carbon, and it’s alkaline in nature which means it increases the pH of soil.

But not all FDE will have the same amount of nutrients – it all depends on the type of effluent management system you have at your farm.

It’s important to get the right size of your FDE storage facility and effluent block that is just the right fit for your farm.

You can get some help by using the following tools:

- Dairy Effluent Storage Calculator (DESC): This calculator uses factors like the size of the herd, soil type, rainfall and features of the system to tell you exactly how much storage is required.

- Overseer: This is a computer program that calculates the size of the effluent block using the number of cows and some other factors to make sure that the N loading is less than 150 kg N/ha/yr.

You could also log on to Pasture.io and check out all our varied plans that will help record all aspects of your farming with precision.

So now that you’re clear about how you can figure out how much effluent block you need, let’s discuss how to apply the effluent.

Applying effluents is typically done via land. You need to consider two main aspects – timing and rate of application.

Effluent Application to Pasture:

- Timing: As we discussed earlier, it all comes down to soil moisture deficit. Spread effluent only when there is sufficient soil moisture deficit. If the soil is too wet it causes either leaching or runoff.

- Rate/depth of application: Make sure that the effluent is applied evenly, at a rate that can seep into the soil and not just drain off.

- Wherever you can, leave a buffer strip next to your farm boundaries and waterways. Be strict about following your consent conditions and regional rules!

Effluent Application to Crops:

Why should you use effluent to grow crops?

- It’s a great source of nitrogen, phosphorous, potassium and some other micro and macronutrients that can be used to grow high-value crops.

- Many forage and arable crops can easily absorb the nutrients present in the effluent.

- Effluents are rich in organic matter and help make the soil richer. It also benefits certain soil properties like organic matter content, water holding capacity and soil structure.

As mentioned earlier, based on the DM content in the effluent, they are applied to land either by spraying using irrigation equipment, pumped under pressure from slurry tankers, or applied via muck spreaders.

Any equipment used for spreading effluent is very heavy and can damage the pasture and soil, especially around the gate entrances.

Your soil type should be able to support this heavy machinery.

Towing heavy quantities of liquids especially on slopes should only be done by an experienced and skilful driver.

Loading your effluent:

Make sure your loading sites and fencing allow vehicle access.

All pond banks and bunker walls should be able to take the weight and force of the machinery that will be operated near them.

Your staff and contractors should be instructed about safety hazards.

Slurry tankers draw effluent from a pond using a PTO pump. During this, the suction pipe should not be allowed to rest on synthetic liners as it could cause a hole in it.

Effluent must be stirred well so that the layers are liquid before removing it from storage.

Excavation equipment can be used for emptying effluent solids bunkers. But, these must not come in contact with clay or synthetic liners as this could be damaged.

Vehicle access must be designed to hold the heavyweight of equipment that is fully loaded.

Do think about the below points before you choose your spreading equipment and method:

- The solid content of the effluent

- The nutrient value of the effluent

- Condition of the soil

- Travel distance between the effluent storage area and the application area

- Consent conditions and council rules for applying effluent

- Where you’re applying the effluent – is it pasture or cropping land.

Caring for the Environment:

Nitrogen, phosphorous and E Coli in the effluents can contaminate groundwater and surface water while:

Leaching – Leaching happens when the contaminants pass through the soil profile in drainage and leak below the active root zone of the plant. This is a major way that Nitrogen is lost.

Runoff: Runoff happens when contaminants are transported across the soil surface during overland flow. This is the major way that phosphorus is lost.

So how do you make sure that leaching doesn’t happen and your water and environment are protected?

- Make sure the correct amount of nutrient is applied

- Make sure there is an active sink for plant-available nutrients

- Follow a good system when applying effluent to high-risk soils.

And how do you prevent runoff?

- Incorporation of effluent – Here, nutrients and organisms in the effluent are mixed through the cultivation layer than just being concentrated on the soil surface

- Do not apply effluent when the chances of surface runoff are high – for instance, during the winter season. There should be at least 2 days gap between the application of slurries and solids and periods of rainfall

- If there is a high risk of runoff and if the site is near a water body like a lake or river, establish a buffer zone of at least 3 – 5 meters between the site and the water body.

So now that we’ve learned about how important effluent is to help improve your pasture and reduce fertiliser cost; how a well-designed effluent system can smooth over so many processes in a farm; we hope that you’re armed with all the right information to make all those important decisions that will ensure a good effluent management system!

Happy Farming!

- The Dedicated Team of Pasture.io, 2020-08-31